| Previous Module - Next

Module

Hybrid Electric Vehicles

|

A.Boyali (*) -

C.Pianese (**) - M.Sorrentino (**)

|

|

(*) Istanbul Technical

University - (**) DIMEC, Università di Salerno |

Summary

This section explains the definition

the terms “hybrid” and hybrid electric vehicles, why we need this kind of technology,

a brief history, current hybrid electric vehicle applications and their architecture.

Why Hybrid Electric Vehicles

Before we begin, we should

know what the term “hybrid” means. The term hybrid can be stated concisely

as the use of two or more power sources to operate any kind of system.

In relation to the terminology “hybrid electric vehicles”, it means to

propel the vehicle using two or more power sources such as an electric

motor, an internal combustion engine or solar energy.

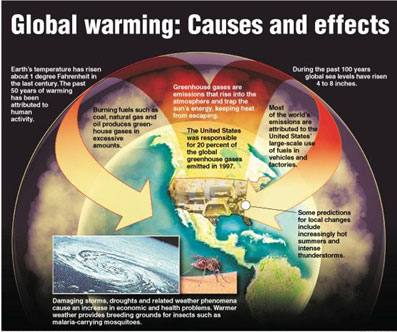

The world’s population is increasing day by day. This will give rise to an increase in the mobility requirements of our population. In contrast, natural resources are moving to the verge of a dangerous balance point due to increased air pollution and its detrimental effects on nature. This is because current vehicles are mostly propelled by internal combustion engines that use fossil fuels. The contribution of road vehicles to air pollution and global warming due to the their carbon monoxide emission is very high. For this reason, scientists and researchers are trying to find new energy sources to alleviate the exhaust emissions emitted by road vehicles.

Figure 1. Global warming and effects

(Source: www.augustachronicle.com )

There are clean alternative energy sources such as hydrogen

and electricity. But the infrastructure is not mature enough and the travel

range with these sources cannot compete with the range available by fossil

fuels. An intermediate solution is thus required. The remedy is hybrid

vehicles.

Brief History of Hybrid Electric Vehicles

Although the history of hybrid

electric vehicles dates back to the 17th century, the first mass

produced hybrid electric vehicle, the Toyota Prius, was introduced in 1997 to

the Japanese market. After this step of Toyota, Honda introduced the Insight

model in 2000.

How a Hybrid Electric Vehicle Works

Hybrid electric vehicles use two

propulsion units. These are an electric motor and an internal combustion engine.

During vehicle motion, these two hybrid electric vehicle power sources are stepped

in from time to time to achieve low fuel consumption and low greenhouse gas

emissions. The main components of hybrid electric vehicles are the electric motor

also used as a generator, the batteries and the coupling devices (see Fig. 2).

Figure 2. Components

of Hybrid Electric Vehicles

(Source: http://www.fueleconomy.gov/feg/hybridtech.shtml)

The electric motor supplies its

energy from the batteries whereas the internal combustion engine uses the fuel

tank for this purpose. Electric motor and internal combustion engines are connected

to each other via mechanical devices. Battery energy is replenished in two ways

during travel of hybrid electric vehicles. One of them is regenerative braking.

The latter one is operating the electric motor as a generator to generate electricity

during normal operation.

There are mainly two different

architectures of a hybrid electric vehicle which are the series and the parallel

architectures.

Series Hybrid Electric Vehicles

In the series hybrid configuration,

the internal combustion engine is only used to charge the batteries. There is

no mechanical connection between the electric motor and the internal combustion

engine (Fig 3.). When the charge of the battery reaches it’s allowed minimum

level, the internal combustion engine starts to charge the battery. When the

battery is fully charged, the internal combustion engine shuts off. In this

configuration, the internal combustion engine runs at its most efficient region.

The main disadvantage of this configuration is that, there are energy losses

during the conversion of energy from fuel energy to electricity and from electricity

to mechanical energy.

Figure 3. Series Hybrid

Electric Vehicle Configuration

(Source: http://www.toyota.co.jp/en/tech/environment/ths2/what.html)

Parallel Hybrid Electric Vehicles

In the parallel configuration,

both the electric motor and the internal combustion engine drive the wheels

according to preferred efficiency paths. The electric motor and the internal

combustion engine are coupled in a parallel manner. If the charge of battery

is low, the electric motor acts as a generator to replenish the battery.

Figure 4. Parallel

Hybrid Electric Vehicle Configuration

(Source: http://www.toyota.co.jp/en/tech/environment/ths2/what.html)

Energetic benefits of vehicle hybridization

The positive impact of vehicle

hybridization on fuel economy is twofold. Fist of all, the presence of

battery allows operating the engine mostly at its best efficiency. For

the series structure, this is achieved by designing the powertrain in

such a way that the engine works at one operating condition, corresponding

to its max conversion efficiency. Therefore, the peaks in power demand

are met by the batteries. For the parallel lay-out, the engine is better

operated with respect to conventional vehicle, mainly because of two reasons:

downsizing and opportunity of turning off the engine during urban driving,

where ICE fuel economy is usually very low. In this case, the depletion

in battery state of charge is compensated by turning on the engine in

highway routes and demanding more power to recharge batteries.

The second important benefit relates to regenerative braking. Through

such process, the negative torque required to slow down the vehicle is

provided by the electric motor/generator, in both series and parallel

structure. Therefore, the vehicle kinetic energy, which is generally lost

in heat in conventional vehicles, can be recovered and restored in the

battery pack. Regenerative braking significantly contributes to decreasing

fuel economy. As an example, in urban driving (i.e. ECE driving schedule)

the fuel savings obtained via regenerative braking reaches up to 15/20%

with respect to same power-to-weight-ratio conventional cars.

Top - Previous

Module - Next Module

|