Photo-Voltaic Panels

|

M.Cricchio,

L.Ferrazzano, A.Vergato (*) - Linguistic Mediator: R.Triggiano (*)

|

|

(*) Istituto Alfano

I

|

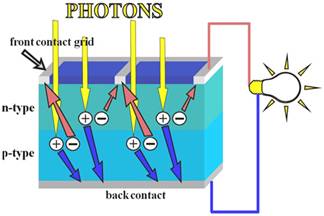

Photovoltaic cells.

A solar cell, or photovoltaic cell, is a semiconductor

device that converts photons (light) into electricity. Fundamentally,

the device needs to fulfill only two functions:

- Photogeneration of charger carriers (electrons and holes) in a light-absorbing

material.

- Separation of the charge carriers, preferably to a conductive contact

that will transmit the electricity.

The conversion is called “photovoltaic effect”: it consists in generation

of electromotive force. The most common configuration of this device,

the first generation photovoltaic, consists of a large-area, single layer

p-n junction diode, which in the presence of sunlight is capable of generating

usable

electrical energy. These cells are typically made using a

silicon p-n junction. However, successive generations of photovoltaic cells that

may improve the photoconversion efficiency are currently being developed.

The second generation of photovoltaic materials is based on multiple layers

of p-n junction diodes. Each layer is designed to absorb a successively

longer

wavelength of light (lower energy), absorbing more of the solar

spectrum and increasing the amount of electrical energy collected. The

third generation of photovoltaics is very different, and is broadly defined

as a semiconductor device which does not rely on a traditional p-n junction

to separate photogenerated charge carriers. They include dye sensitzed

cells, organic polymer cells, and quantum dot solar cells. The absorption

of photons creates electron-hole pairs, which diffuse to the electrical

contacts and can be extracted to power electrical devices. Light generation

of carriers Solar cells have many applications. They are particularly

well suited to, and historically used in, situations where electrical

power from the grid is unavailable, such as in remote area power systems,

Earth orbiting satellites, handheld calculators, remote radiotelephones

and water pumping applications.

When a photon…

When a

photon of light hits a piece of silicon, one of two things can

happen. The first is that the photon can pass straight through the silicon

(if the

energy of the photon is lower than the bandgap energy of the silicon

semiconductor). The second thing that can happen is that the photon is

absorbed by the silicon (if the photon energy is greater than the bandgap

energy of silicon). When a photon is absorbed, its energy is given to

an electron in the crystal lattice. Usually this electron is in the

valence band, and is tightly bound in covalent bonds between neighboring atoms,

and hence unable to move far. The energy given to it by the photon "excites"

it into the

conduction band, where it is free to move around within the

semiconductor. The covalent bond that the electron was previously a part

of now has one less electron - this is known as a hole. The presence of

a missing covalent bond allows the bonded electrons of neighboring atoms

to move into the "hole," leaving another hole behind, and in this way

a hole can move through the lattice. Thus, it can be said that photons

absorbed in the semiconductor create mobile electron-hole pairs.A photon

only needs to have energy greater than the band gap energy to excite an

electron from the valence band into the conduction band. However, the

solar

frequency spectrum approximates a

black body spectrum at ~6000 K,

and as such, much of the solar radiation reaching the

Earth is composed

of photons with energies greater than the band gap of silicon. These higher

energy photons will be absorbed by the solar cell, but the difference

in energy between these photons and the silicon band gap is converted

into heat (via lattice vibrations - called

phonons) rather than into usable

electrical energy.

|

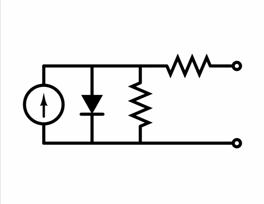

Equivalent circuit of a solar cell

To understand the electronic behaviour of a solar cell, it

is useful to create a

model which is electrically equivalent, and

is based on discrete electrical components . An ideal solar cell

may be modelled by a current source in parallel with a diode. In

practice no solar cell is ideal, so a shunt resistance and a series

resistance component are added to the model. The result is the "equivalent

circuit of a solar cell" shown in the picture.

|

Connection to an external load

Ohmic

metal-semiconductor contacts are made to both the n-type and p-type

sides of the solar cell, and the electrodes connected to an external load.

Electrons that are created on the n-type side, or have been "collected"

by the junction and swept onto the n-type side, may travel through the

wire, power the load, and continue through the wire until they reach the

p-type semiconductor-metal contact. Here, they recombine with a hole that

was either created as an electron-hole pair on the p-type side of the

solar cell, or swept across the junction from the n-type side after being

created there. Usually, solar cells are electrically connected, and combined

into "modules", or

solar panels. Solar panels have a sheet of glass on

the front, and a resin encapsulation behind to keep the semiconductor

wafers safe from the elements (rain, hail, etc). Solar cells are usually

connected in

series in modules, so that their

voltages add.

Silicon as a photovoltaic material

Silicon is a semiconductor as a solid material, meaning that there are

certain

bands of energies which the electrons are allowed to have, and

other energies between these bands which are forbidden. These forbidden

energies are called the "band gap".At room temperature, pure silicon is

a poor electrical conductor. In quantum mechanics, this is explained by

the fact that the Fermi level lies in the forbidden band-gap. To make

silicon a better conductor, it is "doped" with very small amounts of atoms

from either group 13 (III) or group 15 (V) of the periodic table. These

"dopant" atoms take the place of the silicon atoms in the crystal lattice,

and bond with their neighbouring Si atoms in almost the same way as other

Si atoms do. However, because group 13 atoms have only 3 valence electrons,

and group 15 atoms have 5 valence electrons, there is either one too few,

or one too many electrons to satisfy the four covalent bonds around each

atom. Since these extra electrons, or lack of electrons (known as "holes")

are not involved in the covalent bonds of the crystal lattice, they are

free to move around within the solid. Silicon which is doped with group

13 atoms (aluminium, gallium) is known as p-type silicon because the majority

charge carriers (holes) carry a positive charge, whilst silicon doped

with group 15 atoms (phosphorus, arsenic) is known as n-type silicon because

the majority charge carriers (electrons) are negative. It should be noted

that both n-type and p-type silicon are electrically neutral, i.e. they

have the same numbers of positive and negative charges, it is just that

in n-type silicon, some of the negative charges are free to move around,

while the converse is true for p-type silicon.

Semiconductor diodes

In a

p-n junction, conventional current can flow from the p-type side

(the

anode) to the n-type side (the

cathode), but not in the opposite

direction and the current-voltage, or I-V, characteristic curve is ascribed

to the behavior of the so-called

depletion layer or depletion zone which

exists at the

p-n junction between the differing semiconductors. When

a p-n junction is first created, conduction band (mobile) electrons from

the N-doped region diffuse into the P-doped region where there is a large

population of holes (places for electrons in which no electron is present)

with which the electrons "recombine". When a mobile electron recombines

with a hole, the hole vanishes and the electron is no longer mobile. Thus,

two charges carriers have vanished. The region around the p-n junction

becomes depleted of

charge carriers and thus behaves as an

insulator.

However, the

depletion width cannot grow without limit. For each electron-hole

pair that recombines, a positively-charged dopant ion is left behind in

the N-doped region, and a negatively charged dopant ion is left behind

in the P-doped region. As recombination proceeds and more ions are created,

an increasing electric field develops through the depletion zone which

acts to slow and then finally stop recombination. At this point, there

is a 'built-in' potential across the depletion zone. If an external voltage

is placed across the diode with the same polarity as the built-in potential,

the depletion zone continues to act as an insulator preventing a significant

electric current. However, if the polarity of the external voltage opposes

the built-in potential, recombination can once again proceed resulting

in substantial electric current through the p-n junction.

Types of Silicon Solar Cells

Crystalline silicon solar cells come in three primary categories:

- Single crystal or monocrystalline wafers made using the

Czochralski process (or CZ). Most commercial monocrystalline cells have efficiencies

on the order of 16–17%. Single-crystal cells tend to be expensive, and

because they are cut from cylindrical ingots, they cannot completely

cover a module without a substantial waste of refined silicon. Additionally

monocrystalline panels have uncovered gaps at the corners of four cells.

- Poly or multi crystalline silicon solar cells are made from cast

ingots - large crucibles of molten silicon carefully cooled and solidified.

These cells are cheaper than single crystal cells and only slightly

less efficient (typically ~15–16%). They can also be formed into square

shapes that cover a greater fraction of a panel than monocrystalline

cells.

- Ribbon silicon is formed by drawing flat thin films from molten silicon

having a multicrystalline structure. These cells have even lower efficiencies

(~13.5–15%), but there is very little silicon waste, as this approach

does not require sawing from ingots.

All three of these technologies are wafer-based manufacturing. In other

words, in each of the above approaches, self-supporting wafers 180-240

micrometres thick are processed into solar cells and then soldered together

to form a module.

- Amorphous silicon films (a-Si) or thin-film silicon solar cells are

fabricated using chemical vapor deposition techniques, typically plasma

enhanced (PE-CVD). These cells have low efficiencies of around 8%, however

they are much less costly to produce.

Amorphous silicon has a higher bandgap (1.7 eV) than crystalline silicon

(c-Si) (1.1 eV), which means it is more efficient to absorb the visible

part of the solar spectrum, but it fails to collect an important part

of the spectrum : the

infrared. As nanocrystalline Si has about the same

bandgap as c-Si, the two material can be combined by depositing two diodes

on top of each other creating a layered cell called a tandem cell. The

top cell in a-Si absorbs the visible light and leaves the infrared part

of the spectrum for the bottom cell in nanocrystalline Si. A patented

silicon thin film technology being developed for building integrated photovoltaics

(BIPV) is semi-transparent solar cells which can be applied as window

glazing. These cells function as window tinting while generating electricity.

Links

http://www.fsec.ucf.edu/pvt/pvbasics/ (make it yourself)

http://www.re-energy.ca/pdf/cp_solarcar.pdf

http://home.earthlink.net/~bdewey/EV_solarpower.html (solar glossary), (solar history timeline)

http://www.eere.energy.gov/solar/photovoltaics.html

Top - Previous

Module - Next Module |