The Prototype

Introduction

In this project, a hybrid

solar vehicle prototype including a thermal engine, an electrical

motor/generator, a battery pack and photovoltaic panels will be developed

and tested. Design, assemblage and testing processes will be presented

on this web site, with particular care of didactic

sides. Design progresses may be followed through the roadmap

and photo

gallery. Within project deadline, the prototype will be tested and

presented to the media and information agencies.

The Choice

In the first stage of the project, different options

have been investigated to build the hybrid solar vehicle prototype. First

of all, it has been considered either to build a new vehicle

all over again or to develop the project starting from an existing

car. Although the first solution appeared to be interesting,

it was not feasible and consistent with time and budget limits. Moreover,

the second option offered a better chance to apply previous know how and

theoretic analyses. At that point, a vehicle typology had to be selected:

a kart or a car, with thermal

or electrical engine. Finally, an existing electric

vehicle was chosen as basic structure for prototype development.

The Structure

A “Series Hybrid Vehicle”

configuration seems to be the most suitable solution to match the framework

chosen. In this case, traction power is supplied only by the electrical

motor (EM/EG), which may operate also as generator during braking mode

(regenerative braking), adopting one of the electric vehicle energy recovery

strategies. Photovoltaic panels (PV) and the motor/generator system (ICE/EG)

either supply power to the electrical motor or charge the battery pack

(Battery), accordingly to control system strategies (Vehicle Management

Unit, VMU). Further details are available in On-line

simulator section.

Series Solar Hybrid Vehicle Typology

The Electric Vehicle

A “Porter Glass Van” by Microvett has been selected

to develop the prototype. It is a light duty vehicle suited for urban

and protected areas, due to the lack of gas emissions and noise. A “Porter

Glass Van” has been provided to the research group by Automobile

Club Salerno (ACS), one of the project sponsors.

Porter

Glass Van donation to research group by ACS

A significant surface for photovoltaic panels housing

is available on the vehicle roof, while motor/generator and control systems

may be placed in the large trunk. The powertrain includes an electric

motor fed by batteries placed under the driver and passenger compartment.

The electric motor may be reached lifting driver seat.

|

The Rear Bonnet |

Electric Motor |

Transmission Shaft |

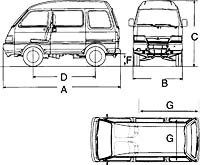

Electric vehicle technical data

Vehicle technical data such as typical sizes, overall volumes,

mass distribution, power provided by batteries and so on are listed in

the following tables.

Sizes |

Meters |

A |

3.560 |

B |

1.395 |

C |

1.870 |

D |

1.810 |

F |

0.540 |

G |

0.793 |

| Engine |

Direct Current Motor |

| Voltage

|

84 V |

| Nominal

power |

9 kW |

| Cooling

flow |

Air |

| Battery pack |

14 6V modules - 180 Ah Pb-Gel sealed, without maintenance |

| Battery charger |

On board - 3 kW - 230 V (standard industrial monophasic

plug) |

| Charging

time |

8 h |

| Rapid

charging |

5 kW - 380 V |

| Rapid

charging time |

2 h 45' @ 80% State of charge |

| Maximum

speed |

60 km/h |

| Range |

70 km in urban duty cicle |

| Transmission |

Direct to the rear axle |

| Steering

radius |

3,7 m |

| Seats |

4 |

Photovoltaic Panels

Referring to photovoltaic panels, different options have been investigated

and proper choices have been made:

- What kind of panels has to be used? In order to work

on a feasible solution, standard production silicon polycrystalline

panels have been selected, rather than high efficiency gallium arsenide

panels, capable to assure high performance but extremely expensive.

- A single panel or many smaller panels? The second

option has been followed to optimize single panel control as a function

of temperature and incoming solar radiation conditions, that may vary

on different panels.

- How may panels be mounted on the vehicle? May they

be integrated in the roof or an external support has to be provided?

First solution guarantees a better aerodynamics and an enjoyable look.

Second option assures higher flexibility during design stage and suggests

innovative ideas. For example, when vehicle is parked, panel orientation

may change following sun position. Finally, a travelling platform has

been chosen, taking into account that aerodynamic losses are negligible

due to vehicle low speed. Following the roof profile by means of two

articulations, an aluminium platform has been built by Saggese company

and donated to the research group.

|

|

|

|

| |

The support for solar panels |

The solar panels are on the roof! |

The motor/generator system

Firstly, we have tried to use a motor-generator system

offered by Lombardini: a 15 KW two-cylinder gasoline engine water cooled.

A solution characterized by a favourable power to weigth ratio, by limited

sizing and power level adequate to vehicle demand.

|

|

Scheme of the Lombardini motor-generator system |

Torque, power and specific consumption of

Lombardini group |

The technical data are summarized in the following table:

Lombardini 500cc LGW523 ENGINE

Max power 15 [kW] @ 5000 [rpm]

3 phase induction MACHINE 15 [kW] power rated

0 - 6000 [rpm] speed range

200 - 400 [V] DC voltage range

100 [A] DC max current

|

Lombardini Motor-Generator - Technical Data |

In order to remove the heat generated by the the cooling

system, the original radiator

used on the vehicle has been recovered and mounted, at CIMEP laboratories.

Moreover, intake

air inlet and exhaust

gas discharge outlet have been realized.

|

|

|

The Lombardini group |

The generator is mounted on board |

Working at CIMEP Labs |

This choice has posed some additional problems:

- the output voltage was higher than the one needed to charge the batteries;

- electric generator power was higher and not compatible with the circuits

already mounted on board;

- the electric machine needs a complex control system to work as motor

during start-up and to shift to generator mode after thermal engine

start.

A second motor-generator group

The solution of these problems did not appear compatible with the time

scheduling of the project. Therefore, a second solution has been chosen:

a 6 KW YANMAR S6000 single-cylinder Diesel engine, air cooled, with electric

starter. This generator, although less powerful respect to Lombardini,

allowed to overcome the problems cited in 1,2,3. In particular, the electric

output, at 230 V, was directly linkable to the vehicle circuitry. Technical

data of YANMAR group are available at this

link.

|

|

The YANMAR motor-generator system |

The YANMAR motor-generator system on the back

side of the vehicle |

The YANMAR has been soon renamed "o' per e o' muss",

thanks to its similarity with the groups used by the street vendors of

the famous neapolitan speciality.

The group has been mounted on the back trunk, using the mechanical supports

and the apparatus already available on board. It has been necessary to

disable a security block that was preventing battery recharging when the

vehicle was moving. Therefore, the engine start has been automated and

suitable potentiometers

have been mounted on gas and brake pedals.

Noise

Of course, mounting a motor-generator into the passenger compartment

is not precisely the best solution in terms of comfort (and safety). Therefore,

an acoustic insulator has been designed and realized,

with the support of Saggese. A window, with double glass layer, has been

inserted to assure back visibility to the driver. A sandwich of insulating

material has been chosen, with lead thin layer and a sponge rubber, to

cut low and hgigh frequencies. In this way, a satisfying noise

reduction has been obtained.

Work in progress...

We are now working to connect an electro-mechanical actuator to regulate

engine load and to mount the equipment for data

acquisition and vehicle control.

…to be continued

|